It is important to explain that dry ice is in fact the solid form of CO2. It has a temperature of –79° C. At atmospheric pressure it evaporates into the air. It is called “dry ice” because it doesn’t contain water. For dry ice cleaning purposes dry ice in the form of granulates of 3 mm diameter, called pellets, is most commonly used.

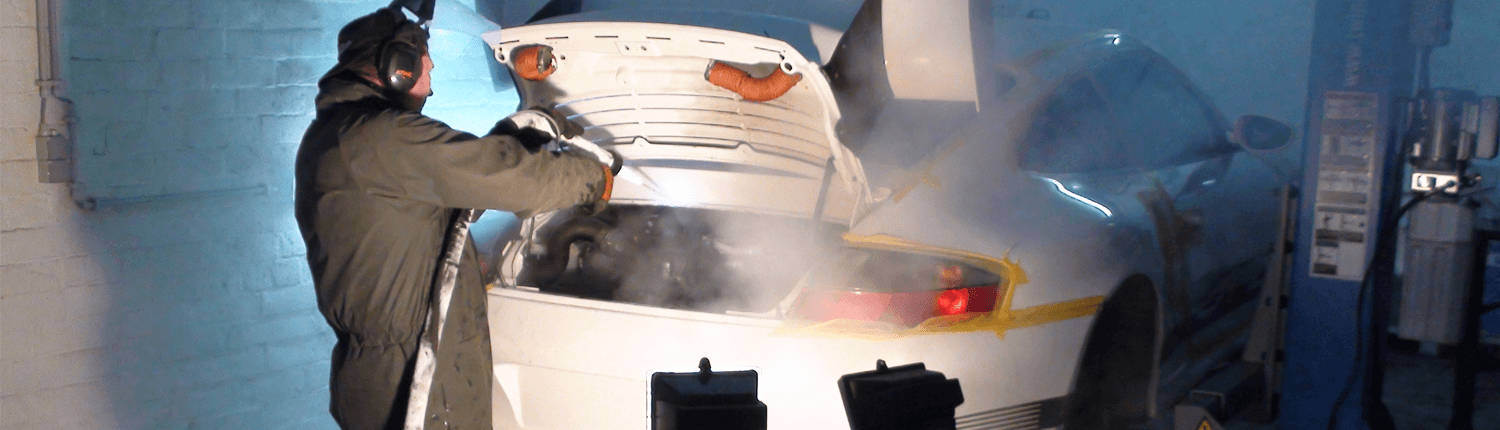

It is a blasting technique that is similar to sand blasting. The advantage of using solid CO2 or dry ice pellets as blasting material is twofold:

Firstly the very low temperature of the dry ice pellets causes the contamination to freeze and contract resulting in the easy detachment of the contaminant from the base material.

Secondly the dry ice pellets vaporize to carbon dioxide gas, which means that only the original contaminant is left for disposal. This natural evaporation of dry ice pellets is a major advantage of the dry ice cleaning method.

We basically use it before we start working on a car or before starting to restore a car. Because the after the dry ice blasting we can make an assessment of the quality of the car. All the road dirt and rash has gone and therefore gives a great visual aspect of the underlying materials. The dry ice blasting’s great advantage is that it does not attack any material (be it electrical, rubber, silver or bronze coated parts etc…) it just thoroughly cleans and bring back the underlying material.

The dry ice blasting is the first step into a restoration process and likewise the first step into a thorough cleaning and detailing job on the car.